-

SupplyingClosed CellSponge RubberNeoprene/SBR/EPDM Blended Sponge

SupplyingClosed CellSponge RubberNeoprene/SBR/EPDM Blended Sponge

About Rubatex

The Rubatex® brand is now owned by GCP Industrial Products, one of North America’s leading providers of industrial rubber materials.

Quality Guaranteed

Our 100% quality guarantee gives you the added confidence and peace of mind that the products you order from us will work for your applications. What it means is, you will never be out of pocket for material that you can not use or sell.

Customer Care

Our premium performance materials are produced to international standards and are used with confidence in a diverse range of industries. We understand quality and consistency are the key to reliability which leads to material success in critical applications.

Technical Support

We sell products, services and more. That “more” is providing the very best customer support, technical advice, we can. We are available to help our customers select materials, work through application issues or overcome engineering challenges.

99.99% Quality Delivered in 2024

Our customers rely on an uninterrupted supply of quality consistent silicone materials in order to keep their customer base happy, and machines running smoothly. As a result, in 2024 we delivered 99.99% quality to our customers. Meaning, 0.01% of the material we delivered was claimed for credit against the purchases our customers made.

Quality Policy

We pride ourselves on providing high quality products to our customers that are consistent with our published product specifications as well as relevant legal and regulatory requirements. Our entire organization is responsible for quality control through our Quality Management System seeking continual improvement by regular review, with all partners being encouraged to cooperate. We are committed to achieving customer satisfaction by the use of quality procedures which are operated to meet or exceed the requirements of the current version of ISO 9001.

Products

We offer a variety of products designed for all your needs.

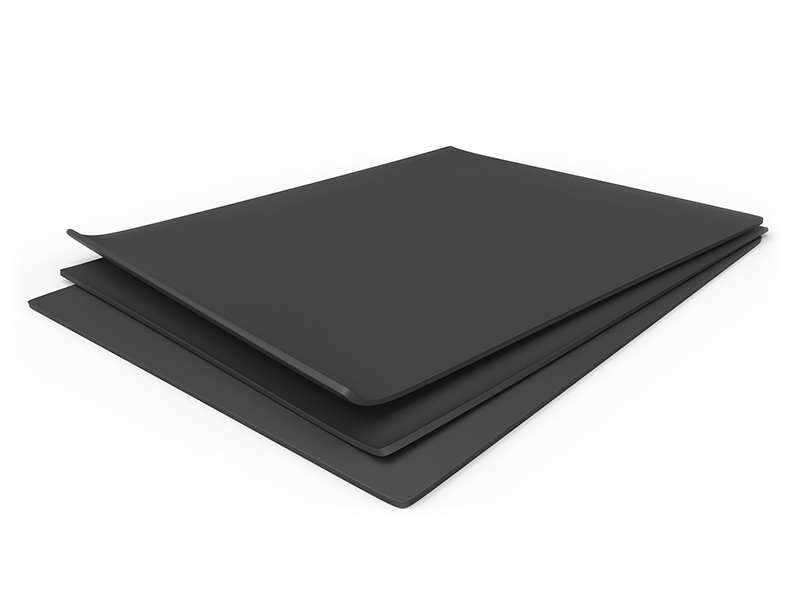

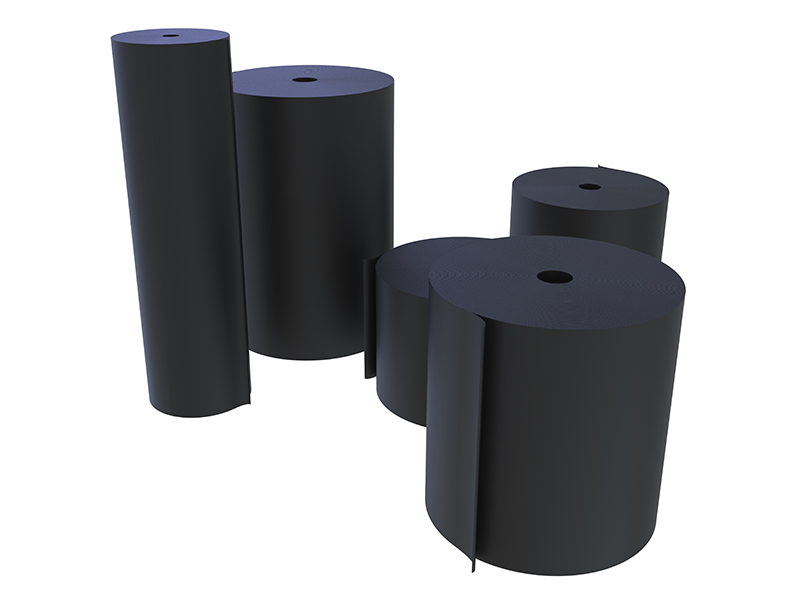

R4261-N

Neoprene/EPDM/SBR Blend.

A black, closed cell, 6±1 pcf density, general purpose material designed to offer the best combination of economies and physical properties per ASTM D1056-14 2A1. Find Out More...

R4271-N

Neoprene/EPDM/SBR Blend.

A black, closed cell, 7±1 pcf density, material with physical properties that meet ASTM D1056-14 2A2. Find Out More...

R4281-N (In Development)

Neoprene/EPDM/SBR Blend.

A black, closed cell, 9±1 pcf density, general purpose material designed for the best combination of price and physical properties per ASTM D1056-14 2A3. Find Out More...

Technical Tips

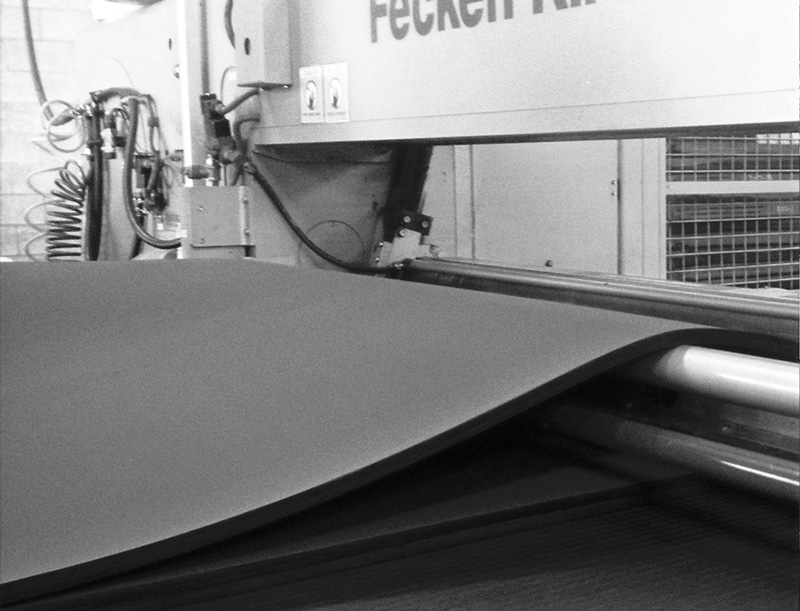

Rubatex sponge rubber products offer customers a highly durable material that is easy to convert or fabricate.

Compared to open cell sponges, our closed cell sponge products provide excellent dimensional stability, low moisture absorption and are higher strength. As such, it is often the sponge rubber of choice for general purpose seal and gasket applications where dust and fluids need to be kept in or out. In addition, to the qualities above our closed cell sponge products are also:

- Lightweight

- Durable

- Compressible

- Flame retardant

- Shock/impact absorbent

- Weatherproof

For more in depth information on our products and closed cell sponge in general please review:

Contact Us

For any inquiries, questions or commendations, please call: 1-855-347-0816 or fill out the following form:

Contact Us

Head Office

678 Belmont Ave W #202

Kitchener, Ontario

Canada, N2M 1N6

sales@rubatexusa.com

Tel: 1-855-347-0816

Fax: 1-866-527-1983